With a decrease in demand for sand cars in the late 2010s, thousands of recently built railcars across North America were poised to idle.

In 2020, a regulatory change allowed railcars to be manufactured using existing equipment. This includes the underframe, composed of products like wheels, trucks, axles and brakes. Greenbrier saw this as an opportunity to solve an industry-wide problem.

Shortly after that change, a cross-functional group at Greenbrier spearheaded a new product offering: Sustainable Conversions™. The Sustainable Conversion™ process involves taking existing railcars to Greenbrier’s production facilities, where experienced teams methodically break them down to their base components to repurpose them as valuable, in-demand railcars capable of carrying other commodities. Once the railcar is disassembled, its reusable parts are sent to standard production lines and are used as part of the new railcar manufacturing process.

The intent behind Sustainable Conversions™ is to reduce waste in the manufacturing process by reusing as much of the railcar as possible. Therefore, Greenbrier’s engineering team plays a significant role in minimizing waste and making Sustainable Conversion™ offerings viable.

The Sustainable Conversion™ offerings include:

- Rebody

- Conversion

- Recertification

- Stretch

- Retrofit

Sustainable Conversions™ lead to reusing many existing components, reducing overall cost and waste.

In fiscal year 2023:

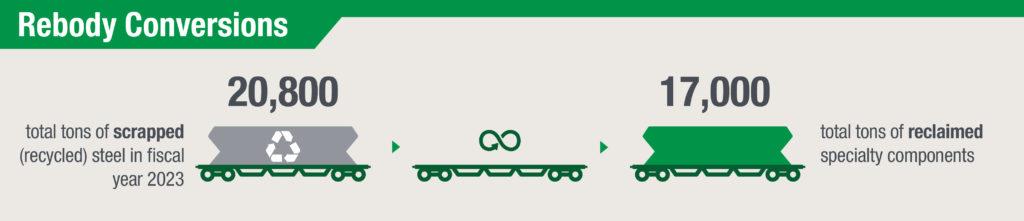

- Greenbrier reclaimed nearly 17,000 tons of specialty components for Rebody Conversions and scrapped (recycled) 20,800 tons of steel.

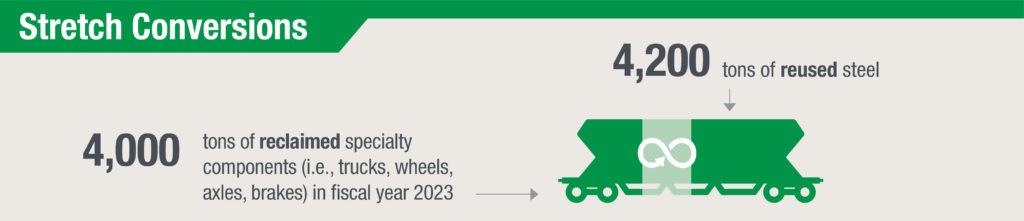

- Greenbrier reclaimed nearly 4,000 tons of specialty components and reused 4,200 tons of steel over 344 total Stretch Conversions in fiscal year 2023. About 258 tons of steel was scrapped (recycled). Stretch Conversions use approximately 65% less steel than newly built ones.

To date, Greenbrier has reused, reclaimed, or recycled more than 45,000 tons of materials. Greenbrier’s Sustainable Conversions™ are an efficient and cost-saving option for customers looking to diversify and optimize their fleets.

Moving freight by rail is among the most environmentally friendly modes of surface transport, and Greenbrier is proud to lead the way through its innovative and sustainable solutions in the manufacturing process.

Learn more about Greenbrier’s Sustainable Conversions™ and Environmental, Social and Governance (ESG) efforts.